When it appeared on the market, 3D printing took the world by storm. People were fascinated with the concept of being able to simply make what they need, instead of trying to purchase it. It made many areas of our lives simple, like making custom casts, machine parts, and furniture, as well as figurines. Seemingly there is nothing 3D printing can’t do.

While most of the public’s focus was on plastic objects, there was a market available for 3D metal printing. Here are the basics.

The Methods

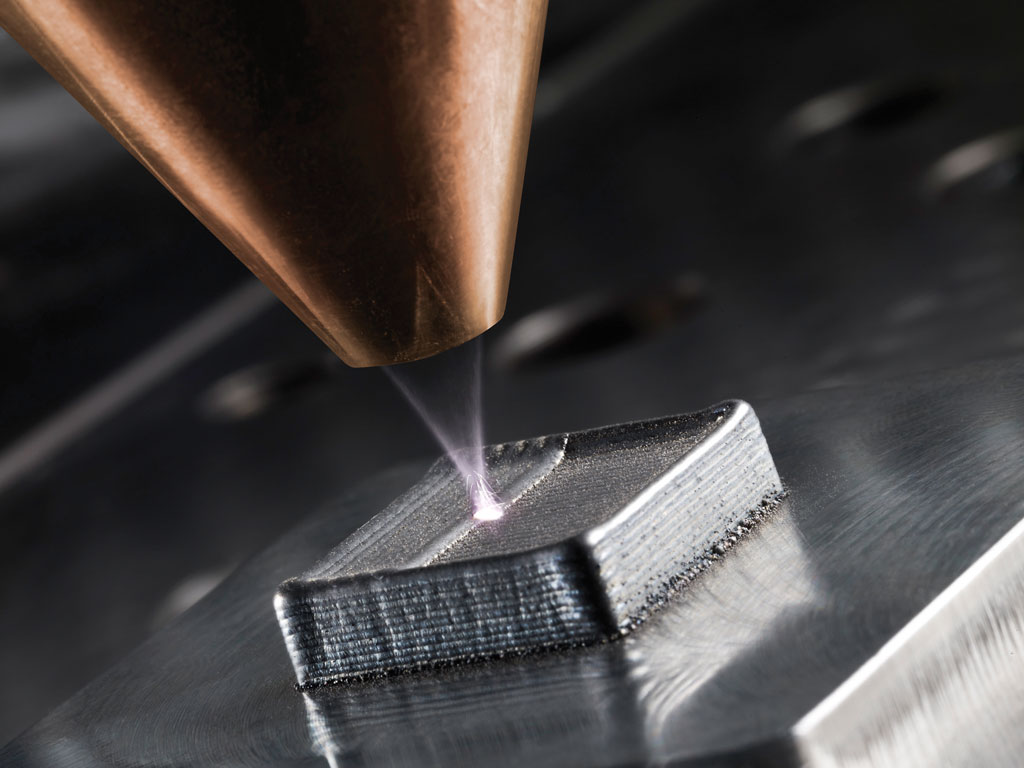

There are three methods by which metal objects are printed. We will briefly explain each one. Selective Laser Melting (SLM) uses the laser to fully melt metallic particles and it keeps a set temperature to do so. Direct Metal Laser Sintering (DMLS) is very similar, with the only major difference being that the powder used in this process is composed of different metals with different melting points. Because of this, the temperature has to be changed during the process.

Last, but not least, we have Electron-Beam Melting (EBM). It completely melts the powder in a vacuum, using an electron beam. Alternatively, wires are used instead of powder and the process is then more similar to plastic 3D printing.

The Process

The process starts with a 3D CAD model that gets sliced into layers. Think of these layers as 2D images stacked one atop another. The model is uploaded into the software that designs parameters. The object is printed layer-by-layer inside a chamber with inert gas. The layers are then fused together. For laser printing, a 200-watt Yb-fiber optic laser is used.

What Metals Are Used?

Depending on the part you need, different metals may be used in their pure forms, or as alloys. As far as pure metals are concerned, you can print objects using copper, gold, titanium, and aluminum. Alloys that are commonly used are stainless steel, maraging steel, and even a super-alloy – Inconel 625. The important thing to point out is that they must be in powder form in order for the 3D printing to work.

What Can I Use It For?

Any time there is a part that would otherwise cost a lot to make, or it is very difficult to produce, metal 3D printing comes to the rescue. The process is much more precise than the traditional manufacturing, so it has applications in medicine, dentistry, aerospace, and producing machine parts.

It is worth noting that medicine has already been experimenting with 3D printing as a way to facilitate repairs on the International Space Station. Instead of waiting several months for adequate parts, the crew could have the desired object within hours.